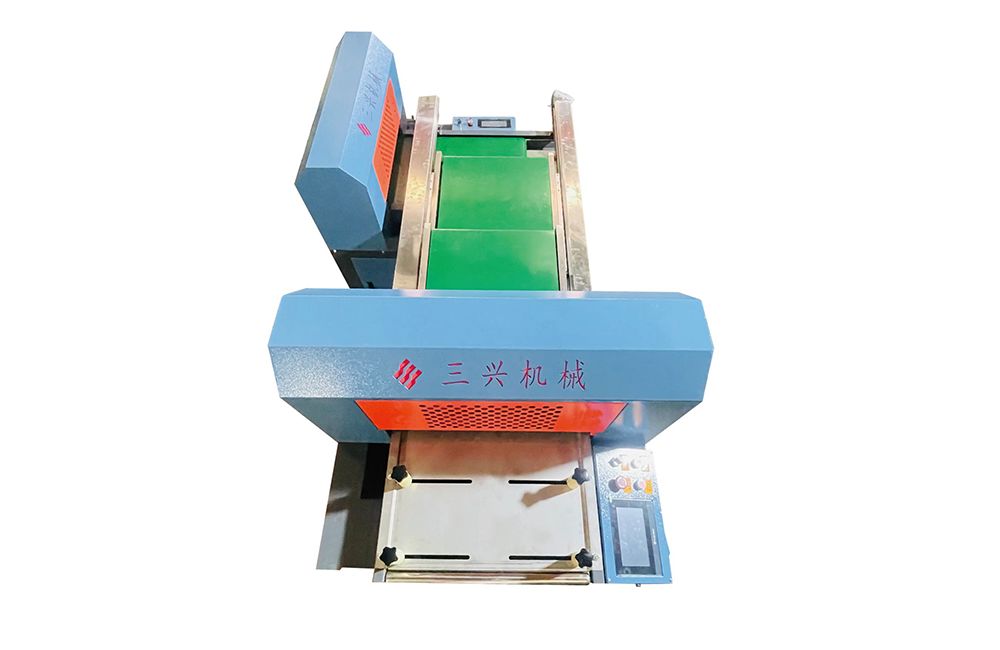

Air Cooling Line

The Air Cooling Line for Rubber Production by Quanzhou Sanxing Machinery Industry And Trade Co., Ltd. is an advanced system designed to efficiently cool rubber products during the manufacturing process. This air cooling line is specifically engineered for high-performance applications in rubber extrusion and molding production, ensuring consistent quality, improved cooling times, and enhanced operational efficiency.

Detailed Product Description

Key Features:

Efficient Cooling Technology:

- The Air Cooling Line is equipped with state-of-the-art cooling technology that ensures fast and uniform cooling of rubber products as they progress through the production line. The system's optimized airflow patterns allow for consistent temperature control, reducing the risk of deformation or damage caused by uneven cooling.

- It uses high-powered fans to create a controlled cooling environment that eliminates the need for water cooling, reducing water consumption and simplifying maintenance.

Enhanced Air Circulation:

- The system is designed to maintain superior air circulation throughout the production process. With multiple high-speed fans strategically positioned along the line, the air is distributed evenly to ensure every part of the rubber product is cooled at the same rate.

- This feature ensures product quality by minimizing the possibility of hot spots or temperature gradients that can affect product strength and elasticity.

Modular Design for Flexibility:

- The modular design of the Air Cooling Line allows it to be easily integrated into existing rubber production lines. Its flexible configuration can be customized to meet specific production requirements, making it suitable for a wide range of rubber products, including extruded profiles, sheets, and molded items.

- The line can be scaled to accommodate different lengths or sizes of rubber products, ensuring that the cooling process is tailored to your specific production needs.

Energy-Efficient Operation:

- Energy efficiency is at the heart of the Air Cooling Line's design. The system uses energy-saving fans and motors that reduce power consumption without compromising on cooling performance. This leads to significant energy savings and reduced operational costs over time.

- The system is equipped with automatic controls that adjust fan speeds based on the temperature of the products, ensuring efficient use of energy during production.

Durable and Low-Maintenance Construction:

- Built from high-quality, corrosion-resistant materials, the Air Cooling Line is engineered for durability and long-term reliability. Its rugged design ensures it can withstand the harsh conditions of industrial production environments, minimizing the risk of breakdowns and extending its operational lifespan.

- The low-maintenance design includes easily accessible components for routine inspections and cleaning, reducing downtime and maintenance costs.

Precise Temperature Control:

- The system is equipped with advanced temperature sensors that monitor the cooling process in real time. This allows for precise temperature control, ensuring that the rubber products are cooled to the exact specifications required for optimal performance and quality.

- The control system is user-friendly, allowing operators to adjust settings as needed to accommodate different rubber materials or product designs.

Noise-Reduction Features:

- The Air Cooling Line incorporates noise-reduction technology, ensuring quiet operation even during high-speed production. This makes the production environment more comfortable for workers and reduces noise pollution in the factory.

- Despite the reduced noise levels, the system delivers powerful cooling performance, ensuring efficient production.

Versatile Application:

- The Air Cooling Line is highly versatile and can be used in a variety of rubber production processes, including extrusion, molding, and calendaring. It is ideal for cooling rubber profiles, tubes, hoses, belts, and sheets, providing reliable performance across different product types.

- This adaptability makes it a valuable addition to any rubber manufacturing setup, capable of handling different cooling demands.

Safety and Compliance:

- Safety is a top priority with built-in safety features such as thermal overload protection and emergency stop mechanisms. The system complies with international safety standards, ensuring that your production facility remains safe for operators.

- The fans and cooling elements are enclosed in protective housings, reducing the risk of accidental contact or injury during operation.

Applications:

- Rubber profiles

- Rubber sheets

- Tubes and hoses

- Molded rubber parts

- Conveyor belts

- Extruded rubber products

Service and Support:

Quanzhou Sanxing Machinery Industry And Trade Co., Ltd. provides comprehensive after-sales service, including installation assistance, training for operators, and ongoing technical support. We offer regular maintenance services and troubleshooting support to ensure that your Air Cooling Line operates at peak efficiency.

Conclusion

The Air Cooling Line from Quanzhou Sanxing Machinery Industry And Trade Co., Ltd. is the ideal solution for rubber manufacturers looking to enhance their production capabilities. Its efficient cooling, energy-saving design, and flexible modular construction make it a valuable investment for any rubber production line. With advanced technology, precise control features, and robust durability, this system ensures high-quality rubber products and smooth, efficient production processes.