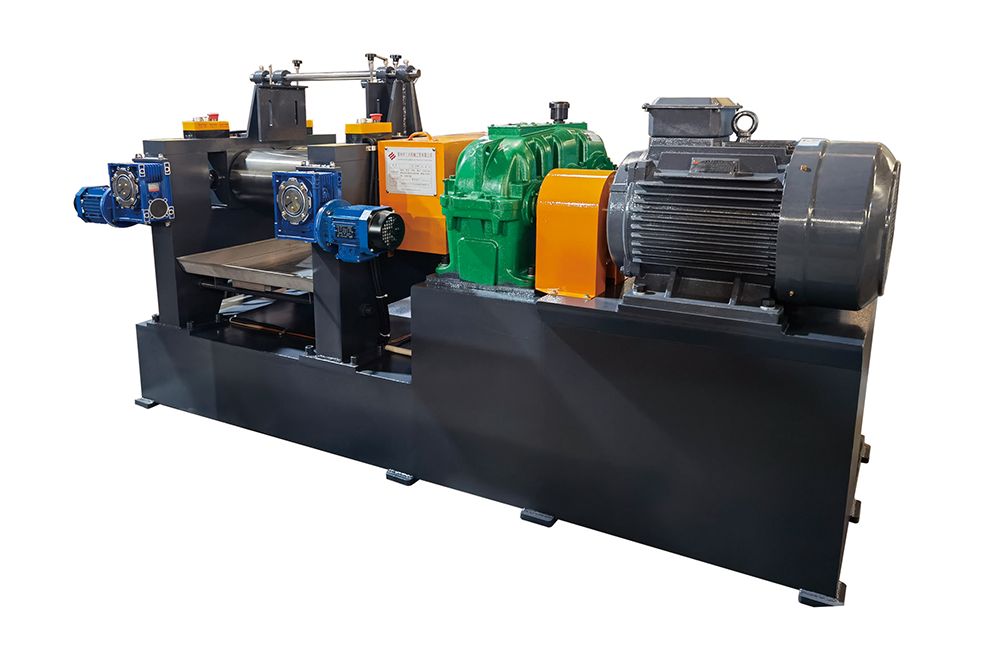

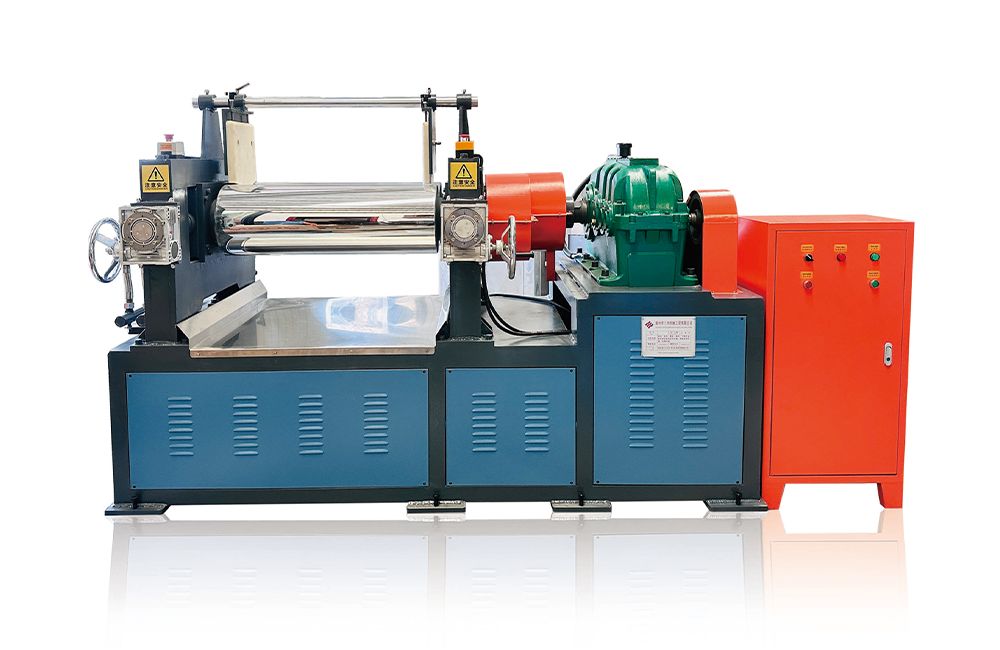

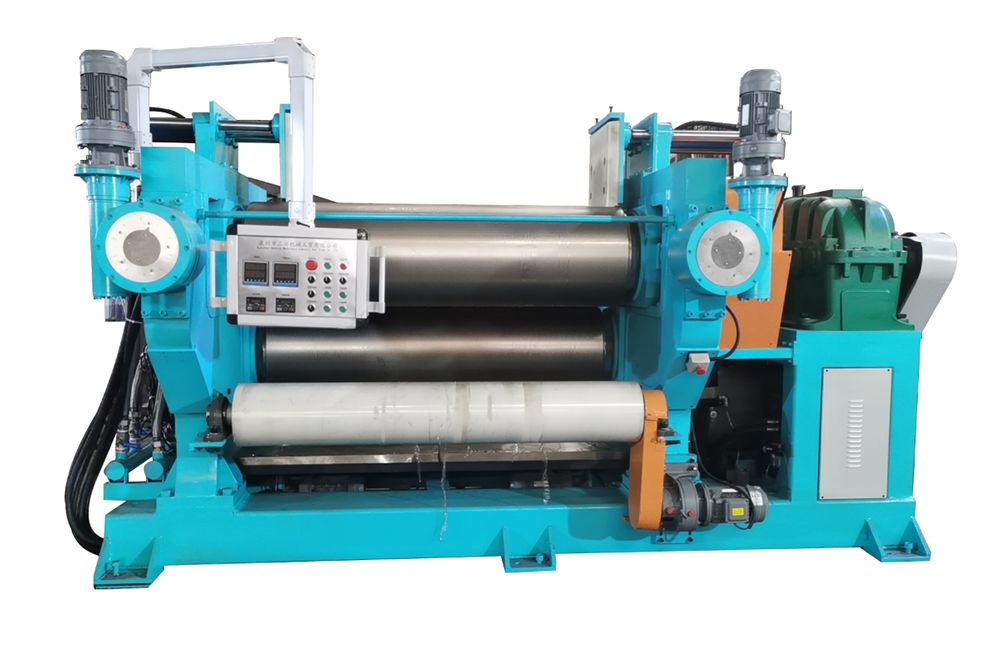

Three-Roller 20-Inch Calender Machine - Model 2

The Three-Roller 20-Inch Calender Machine (Model 2) by Quanzhou Sanxing Machinery Industry and Trade Co., Ltd. represents the pinnacle of precision and efficiency in rubber processing. Designed specifically for industrial-grade applications, this advanced calendering machine ensures optimal material handling and uniformity, producing high-quality rubber sheets and components. With robust construction, automated controls, and a user-friendly interface, this machine is perfect for manufacturers seeking reliability, flexibility, and consistent performance.

Detailed Product Description

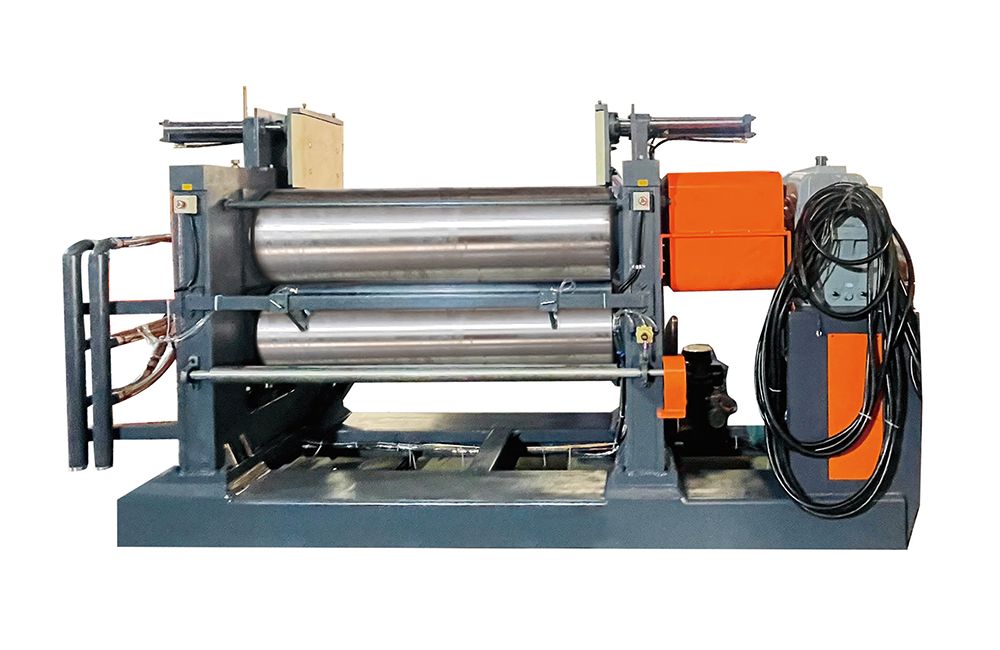

1. Advanced Roller System for Precision Processing

The Three-Roller 20-Inch Calender Machine (Model 2) is built with high-performance rollers that deliver exceptional calendering results.

- 20-Inch Roller Diameter: The machine’s large 20-inch rollers allow for high-volume processing, making it ideal for industrial-scale production. This feature ensures a smooth, even flow of rubber material through the rollers, resulting in consistent thickness and quality across the entire product.

- Durable Alloy Steel Rollers: The rollers are made from high-strength alloy steel, offering superior wear resistance and long-term durability. The surface of each roller is finely polished to minimize friction and prevent material sticking, ensuring a high-quality finish with minimal waste.

- Precise Gap Adjustment: The gap between the rollers can be precisely adjusted to achieve the desired material thickness. This level of control ensures consistent output, regardless of the specific requirements for each production run.

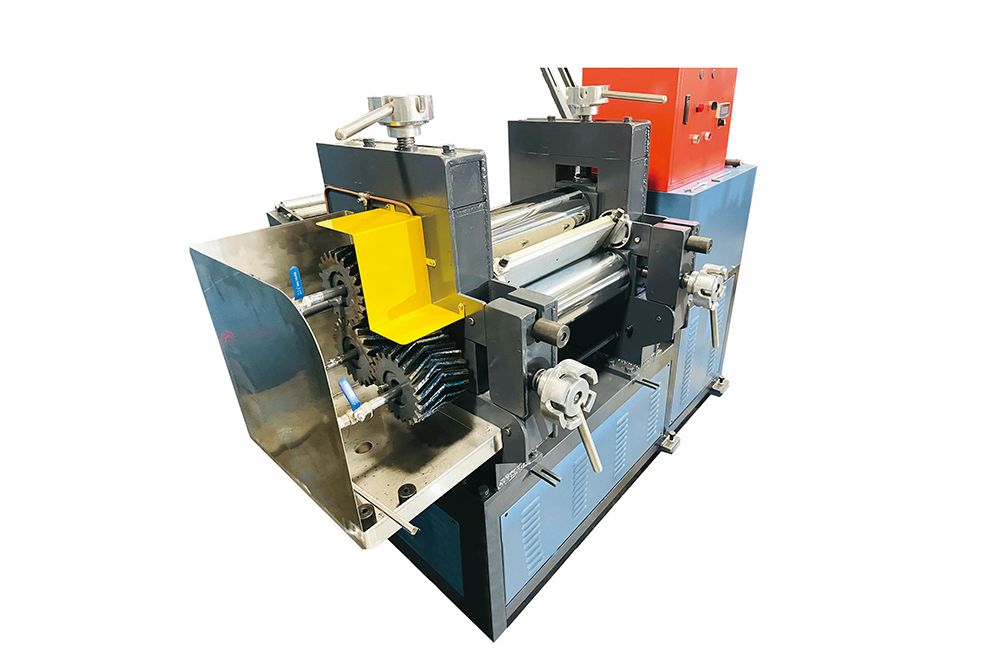

2. State-of-the-Art Control and Automation

This machine incorporates cutting-edge automation and control features, providing manufacturers with unparalleled efficiency and operational flexibility.

- Automated Control System: The intelligent control system allows operators to automate key functions such as roller speed, pressure, and temperature. This not only improves production efficiency but also reduces the risk of human error during operation.

- Intuitive Touchscreen Interface: The machine is equipped with an advanced touchscreen control panel that simplifies operation. From this interface, operators can easily monitor and adjust settings to match production requirements, ensuring that every batch meets exact specifications.

- Programmable Logic Controller (PLC): The PLC system enhances the machine’s automation capabilities, allowing for precise control of the calendering process and enabling operators to set predefined operating parameters for different materials and applications.

3. Robust Structure and Industrial Durability

Engineered to withstand the demands of continuous production, the Three-Roller 20-Inch Calender Machine (Model 2) is built with durability and stability in mind.

- Heavy-Duty Frame: The machine’s reinforced steel frame ensures stability during operation, even when handling large volumes of material. This reduces vibration and ensures that each product is processed with the same level of precision.

- Cooling System for Heat Management: An efficient cooling system prevents overheating during extended operation, ensuring consistent performance and prolonging the lifespan of the machine.

- Corrosion-Resistant Design: The key components of the machine are treated with corrosion-resistant materials, allowing it to perform reliably in harsh industrial environments and ensuring long-term durability.

4. Versatile Applications for Rubber Processing

This calender machine is engineered to handle a wide variety of rubber materials and applications, making it highly versatile for different industries.

- Multi-Material Capabilities: The machine is capable of processing a broad range of rubber materials, including natural rubber, synthetic rubber, and specialty elastomers. This versatility makes it ideal for producing rubber sheets, conveyor belts, tire components, and other high-demand products.

- Customizable Production Parameters: The adjustable roller gap, pressure, and speed settings provide flexibility for manufacturers to fine-tune the machine according to their specific production needs. Whether producing thin rubber films or thicker industrial-grade sheets, this machine offers full control over the final product.

5. Safety and Operational Efficiency

Safety and operational efficiency are paramount in the design of the Three-Roller 20-Inch Calender Machine (Model 2).

- Integrated Safety Features: The machine is equipped with multiple safety features, including protective guards and an emergency stop system, to ensure the safety of operators during production.

- Energy Efficiency: Built with energy-saving technology, the machine minimizes power consumption, making it a cost-effective solution for manufacturers focused on both performance and sustainability.

Commitment to Quality and Innovation

At Quanzhou Sanxing Machinery Industry and Trade Co., Ltd., we are dedicated to delivering superior machinery that meets the highest standards of quality and innovation. The Three-Roller 20-Inch Calender Machine (Model 2) exemplifies our commitment to excellence, combining precision engineering with advanced automation to provide unmatched performance in rubber processing.

As a national high-tech enterprise, we have received numerous patents and earned the trust of customers worldwide. Looking ahead, we will continue to uphold our core values of "Quality Assurance and Technological Innovation," and we look forward to forging successful partnerships with clients around the world. Together, we can achieve excellence in the face of global competition.