What Is A Calendar In Manufacturing

2024-10-29

In the context of manufacturing, a calendar is a crucial piece of equipment that plays a vital role in various processes. It is not the traditional calendar we use to mark dates but a machine that is used for specific operations related to shaping, finishing, and processing materials.

A calendar in manufacturing is typically used to process materials such as rubber, plastics, textiles, and even some types of papers. It consists of rollers that apply pressure and heat to the material as it passes through. This process helps in achieving several desired characteristics. For example, in the rubber industry, a calendar is used to smooth and shape rubber sheets. It can ensure a uniform thickness and surface finish, which is essential for the production of items like tires, rubber belts, and rubber gaskets. The pressure and heat applied by the calendar rollers can also improve the mechanical properties of the rubber, making it more durable and suitable for its intended application.

In the plastics industry, a calendar is used to produce plastic films and sheets with a smooth and even surface. This is crucial for packaging applications where the appearance and quality of the plastic surface are important for printing, sealing, and overall product presentation. The calendar can also be used to apply coatings or laminates to the plastic, adding additional functionality such as barrier properties or enhanced aesthetics.

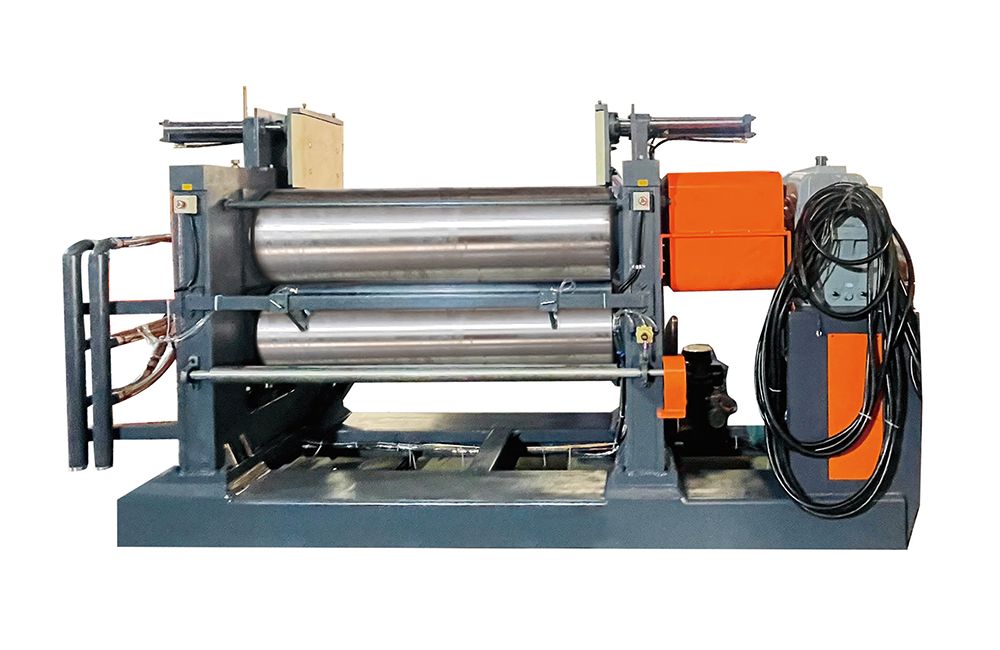

Now, let's focus on the Three-Roller 20-Inch Calender Machine - Model 1. This particular model is designed with specific features and capabilities that make it suitable for a range of manufacturing operations. The three rollers in this machine work together to exert the necessary pressure on the material being processed. The 20-inch width provides a certain capacity and can handle a decent volume of material, making it suitable for medium to large-scale production runs. It is equipped with advanced control systems that allow operators to adjust the pressure, temperature, and speed of the rollers according to the requirements of the material and the desired end product.

For instance, when processing a particular type of plastic, the operator can set the appropriate temperature to ensure that the plastic is in the right state for shaping. The pressure can be adjusted to achieve the desired thickness and smoothness of the plastic sheet. The speed of the rollers determines the production rate, and it needs to be optimized to balance efficiency and quality. The Three-Roller 20-Inch Calender Machine - Model 1 can also be used for research and development purposes in a manufacturing setting. Manufacturers can use it to test new materials or develop new processes by experimenting with different parameter settings.

A calendar in manufacturing is an essential tool that contributes to the production of high-quality materials and products. The Three-Roller 20-Inch Calender Machine - Model 1, with its specific features and capabilities, is a valuable asset in the manufacturing process. Whether it's for producing rubber products with precise dimensions, creating smooth plastic sheets, or other related operations, this machine and the concept of a manufacturing calendar play a significant role in the success of many industries. Understanding their functions and applications is crucial for manufacturers looking to improve their production processes and product quality. So, the next time you come across a well-finished rubber or plastic product, remember the role that the calendar and machines like the Three-Roller 20-Inch Calender Machine - Model 1 have played in its creation.