What Is Calendering Used For

2024-10-29

Calendering is a process that has a wide range of applications in various industries. It involves passing a material between rollers under pressure to achieve specific desired properties and finishes.

One of the main uses of calendering is in the production of rubber and plastic products. In the rubber industry, calendering is used to shape and smooth rubber sheets. It helps in achieving a uniform thickness and surface finish, which is crucial for applications such as tires, conveyor belts, and rubber mats. The process can also improve the mechanical properties of the rubber, making it more durable and suitable for its intended use. For example, in tire manufacturing, calendering is used to create the layers of rubber that make up the tire's structure. The precise control over thickness and texture provided by calendering ensures that the tires have the right characteristics for good traction, durability, and performance on the road.

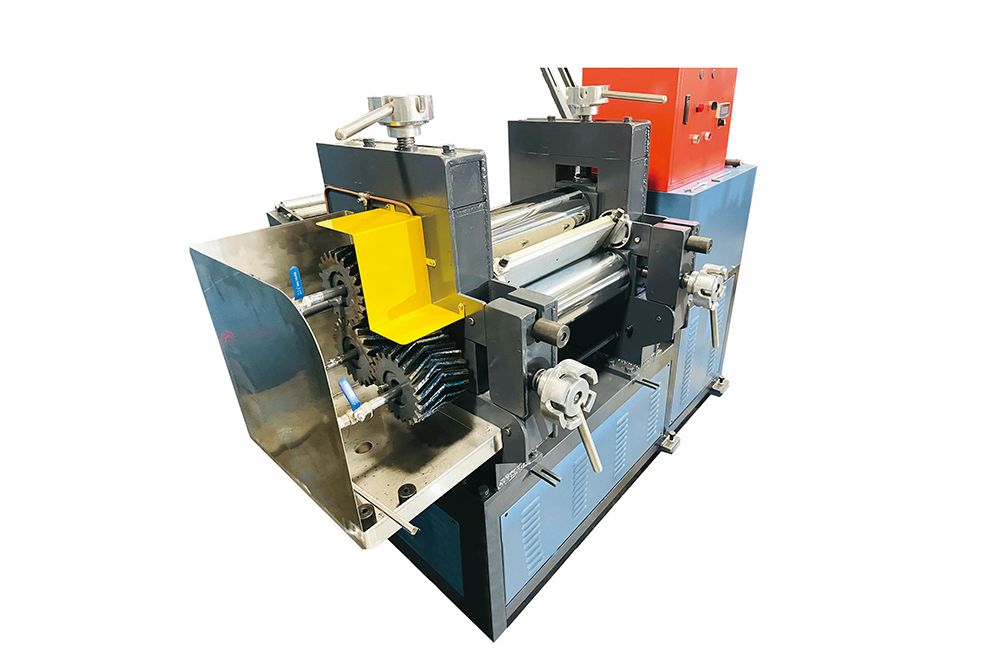

In the plastic industry, calendering is used to produce films, sheets, and coatings. It can be used to make plastic packaging materials with a smooth and even surface, which is important for printing and sealing. The Three-Roller 6-Inch Calender Machine is a specific type of calender that is well-suited for certain applications. With its three rollers and a 6-inch width, it can handle smaller to medium-sized batches of materials. This makes it suitable for businesses that need to produce specialized plastic or rubber products in relatively smaller quantities. The machine's rollers are designed to apply the right amount of pressure and heat to the material being processed, ensuring a consistent quality output.

Calendering is also used in the textile industry. It can be used to finish fabrics, giving them a smooth and glossy appearance. It can improve the drape and handle of the fabric, making it more appealing for clothing and upholstery applications. Additionally, calendering can be used to apply coatings or laminates to fabrics, such as waterproof or flame-retardant coatings. This adds functionality to the fabric and expands its range of uses.

In the paper industry, calendering is used to improve the smoothness and gloss of paper. It can make the paper more suitable for printing and writing, as well as enhance its overall appearance. The process can also help in reducing the porosity of the paper, which can improve its ink absorption and print quality.

The Three-Roller 6-Inch Calender Machine, like other calenders, requires proper operation and maintenance to ensure its efficiency and longevity. Operators need to be trained to set the correct parameters such as roller pressure, temperature, and speed according to the material being processed. Regular maintenance of the rollers, bearings, and drive systems is essential to prevent breakdowns and ensure consistent performance.

Calendering is a versatile process with numerous applications in different industries. The Three-Roller 6-Inch Calender Machine is a valuable tool that can help businesses achieve the desired results in their specific production processes. Whether it's in rubber, plastic, textile, or paper production, calendering plays a crucial role in enhancing the quality and functionality of the final products. Understanding the uses and capabilities of calendering and its associated machinery is essential for businesses looking to optimize their production and meet the demands of the market. So, the next time you see a smooth plastic sheet, a well-finished fabric, or a high-quality paper, remember the role that calendering and machines like the Three-Roller 6-Inch Calender Machine have played in their production.