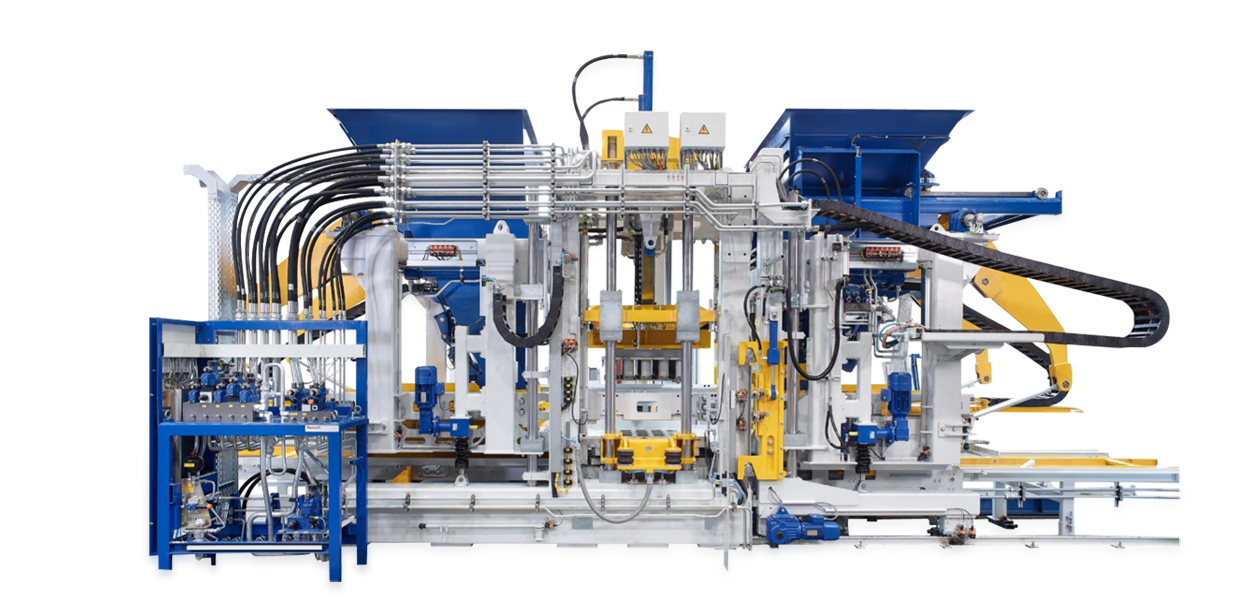

Twin-Conical and Triple-Conical Screw Extrusion Calendering Machines

The Twin-Conical and Triple-Conical Screw Extrusion Calendering Machines by Quanzhou Sanxing Machinery Industry And Trade Co., Ltd. are sophisticated, high-performance machines designed to meet the exacting demands of the rubber and plastics industries. These machines feature innovative conical screw designs that ensure efficient material processing, precise control, and superior product quality. Ideal for producing a wide range of flat products such as sheets, films, and plates, these machines are the perfect solution for manufacturers seeking to enhance productivity and maintain consistent product standards.

Detailed Product Description

Key Features:

Innovative Conical Screw Design:

- Twin-Conical Screw Extruder: The twin-conical screw design is engineered to optimize the feeding and mixing of materials. The conical shape increases the pressure and shear force as the material moves along the screw, ensuring efficient homogenization and thorough melting. This design is particularly beneficial for processing materials that require precise temperature control and uniformity, resulting in high-quality extruded products with minimal variation.

- Triple-Conical Screw Extruder: The triple-conical screw configuration further enhances material handling capabilities, offering even greater efficiency in processing and output. This setup is ideal for complex material formulations, especially when producing multi-layered sheets or products with intricate material properties.

Precision Calendering System:

- The calendering unit is equipped with high-precision rollers that ensure uniform thickness and an immaculate surface finish on the extruded sheets. The rollers are precisely temperature-controlled, allowing for the fine-tuning of product characteristics such as gloss, transparency, and mechanical properties.

- The system's adjustable nip gaps and roller speeds provide flexibility in handling a wide variety of materials, from soft elastomers to rigid thermoplastics, ensuring consistent quality across different product types.

Advanced Control System:

- These machines are equipped with a state-of-the-art PLC control system that offers unmatched precision and ease of use. Operators can monitor and adjust critical parameters, such as screw speed, temperature, and roller pressure, through an intuitive touchscreen interface. This ensures that every aspect of the production process is finely tuned for optimal results.

- The control system also includes real-time monitoring, diagnostic functions, and automated alerts, reducing the risk of downtime and enhancing overall production efficiency.

Energy-Efficient Design:

- The Twin-Conical and Triple-Conical Screw Extrusion Calendering Machines are designed with energy efficiency as a top priority. High-efficiency motors and low-energy heaters are standard features, which reduce energy consumption without compromising production speed or quality. The conical screw design itself contributes to energy savings by ensuring that less energy is required to process materials efficiently.

- These machines are also designed to meet stringent environmental standards, with features that minimize waste and reduce emissions, making them an environmentally friendly choice for modern manufacturing.

Durable and Robust Construction:

- Built with high-strength materials and designed for durability, these machines are capable of withstanding the rigors of continuous, high-load operation. Key components, such as screws, barrels, and rollers, are made from wear-resistant materials, ensuring a long service life and reducing the need for frequent maintenance.

- The machine structure is engineered for stability and minimal vibration, which not only contributes to the longevity of the equipment but also ensures safer operation and consistent product quality.

Versatile Application Range:

- The versatility of these machines allows them to process a wide variety of materials, including natural and synthetic rubbers, thermoplastics, thermosets, and composite materials. They are particularly well-suited for producing high-quality sheets, films, and plates used in industries such as automotive, construction, electronics, and packaging.

- The ability to handle complex materials and produce multi-layered or specialized products makes these machines an invaluable asset for manufacturers looking to diversify their product offerings and meet the evolving demands of their markets.

Applications:

The Twin-Conical and Triple-Conical Screw Extrusion Calendering Machines are widely used in various industries for producing flat products with high precision and consistency. These include the production of rubber sheets, plastic films, flooring materials, conveyor belts, and protective coatings. The machines’ advanced capabilities also make them ideal for developing innovative new products that require intricate material compositions or multi-layered designs.

Service and Support:

Quanzhou Sanxing Machinery Industry And Trade Co., Ltd. is dedicated to providing comprehensive service and support for these machines. We offer full installation and commissioning services, operator training, and ongoing technical assistance to ensure that our customers can achieve maximum productivity and long-term success with our equipment. Our commitment to customer satisfaction is reflected in our prompt and reliable service, which is available whenever and wherever you need it.

Conclusion

The Twin-Conical and Triple-Conical Screw Extrusion Calendering Machines exemplify Quanzhou Sanxing Machinery Industry And Trade Co., Ltd.’s commitment to innovation, quality, and customer satisfaction. These machines are engineered to deliver exceptional performance, precision, and versatility, making them an ideal choice for manufacturers in the rubber and plastics industries. With our advanced technology and comprehensive support services, we are confident that these machines will help our customers achieve their production goals and drive success in an increasingly competitive marketplace.