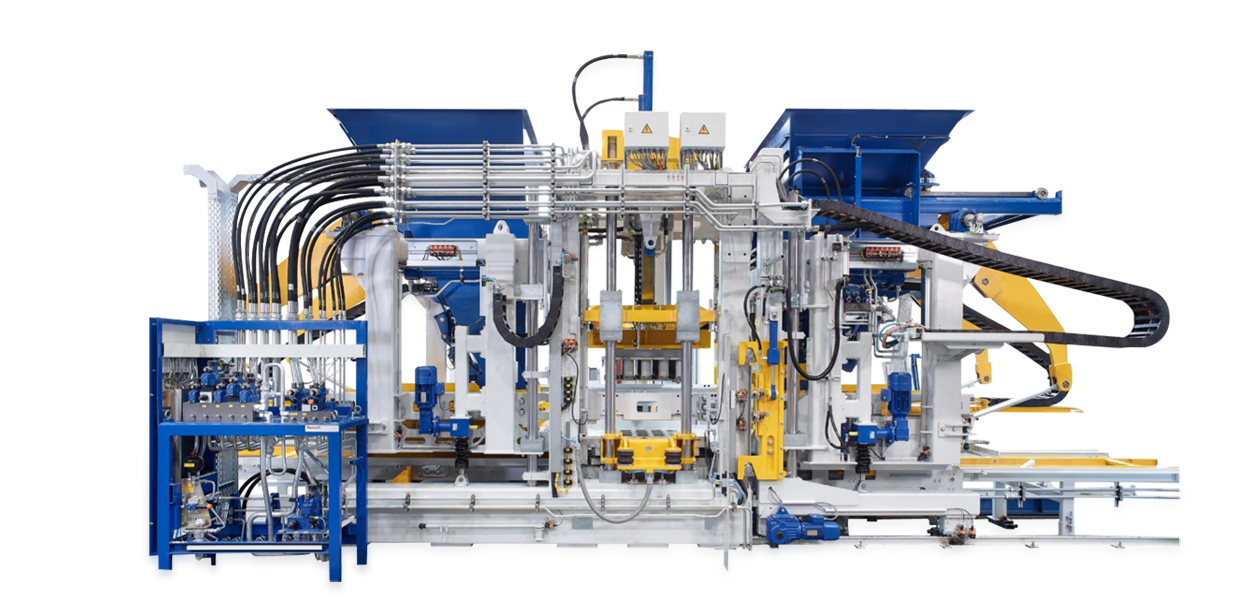

Twin-Screw and Triple-Screw Extrusion Calendering Machines

The Twin-Screw and Triple-Screw Extrusion Calendering Machines by Quanzhou Sanxing Machinery Industry And Trade Co., Ltd. are state-of-the-art equipment designed for high-precision extrusion and calendering processes. These machines are tailored to meet the rigorous demands of the rubber and plastic industries, delivering exceptional performance, superior product quality, and operational efficiency. With advanced screw design and intelligent control systems, these machines are ideal for producing high-quality sheets, films, and other flat products.

Detailed Product Description

Key Features:

Advanced Screw Design:

- Twin-Screw Extruder: The twin-screw configuration is optimized for high-efficiency mixing, melting, and homogenization of materials. The intermeshing screws ensure consistent material flow, reducing shear stress and minimizing thermal degradation. This results in high-quality extruded sheets with excellent mechanical properties and uniform thickness.

- Triple-Screw Extruder: The triple-screw design further enhances material processing capabilities, offering superior mixing performance and improved output rates. This configuration is particularly beneficial for processing high-viscosity materials or when producing multi-layered sheets with complex material compositions.

High-Precision Calendering System:

- The calendering unit is equipped with precision rollers that ensure uniform thickness and smooth surface finish of the extruded sheets. The rollers are temperature-controlled, allowing precise control over the sheet's final properties, such as gloss, transparency, and mechanical strength.

- Adjustable nip gaps and roller speeds provide flexibility in processing a wide range of materials, from soft elastomers to rigid plastics.

Intelligent Control System:

- The machines are equipped with a PLC-based control system that offers precise control over the extrusion and calendering processes. Operators can easily monitor and adjust parameters such as screw speed, temperature, and roller pressure via an intuitive touchscreen interface. This ensures consistent product quality and optimal production efficiency.

- The control system also features real-time monitoring and diagnostic functions, which help minimize downtime and reduce maintenance costs.

Energy Efficiency and Environmental Considerations:

- The Twin-Screw and Triple-Screw Extrusion Calendering Machines are designed with energy efficiency in mind. High-efficiency motors, low-energy heaters, and optimized screw designs reduce overall energy consumption while maintaining high production output.

- The machines are built to comply with environmental standards, featuring low-emission designs and waste-reduction technologies that minimize environmental impact.

Robust Construction and Durability:

- Constructed with high-quality materials, these machines are built to last, even under continuous, high-load operation. Critical components such as screws, barrels, and rollers are made from wear-resistant materials, ensuring long service life and minimal maintenance requirements.

- The entire machine structure is designed for stability and vibration reduction, contributing to consistent production quality and operator safety.

Versatile Applications:

- These machines are highly versatile and can process a wide range of materials, including natural and synthetic rubber, thermoplastics, thermosets, and composite materials. They are ideal for producing high-quality sheets and films used in automotive, construction, electronics, and packaging industries.

Applications:

The Twin-Screw and Triple-Screw Extrusion Calendering Machines are widely used in various industries for producing flat products with precise dimensions and consistent quality. Typical applications include the production of rubber sheets, plastic films, conveyor belts, flooring materials, and protective coatings. Their ability to handle complex material formulations and produce multi-layered products makes them an indispensable tool for manufacturers looking to innovate and stay competitive.

Service and Support:

Quanzhou Sanxing Machinery Industry And Trade Co., Ltd. offers comprehensive service and support for these machines, including installation, commissioning, operator training, and ongoing technical assistance. Our dedicated team of experts is committed to ensuring that our customers achieve maximum productivity and long-term success with our equipment.

Conclusion

The Twin-Screw and Triple-Screw Extrusion Calendering Machines represent the pinnacle of extrusion technology, offering unparalleled performance, precision, and versatility. Developed by Quanzhou Sanxing Machinery Industry And Trade Co., Ltd., these machines embody our commitment to quality, innovation, and customer satisfaction. We are proud to offer these cutting-edge solutions to our customers and look forward to partnering with them to drive success in the competitive marketplace.