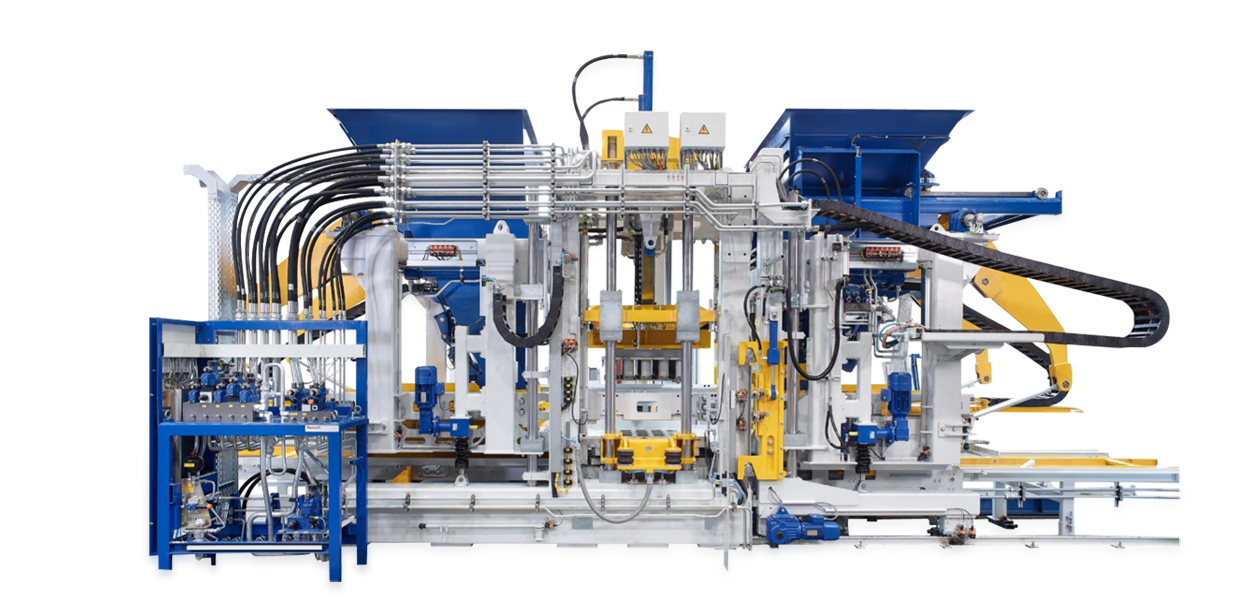

Automatic Punching Press Model 1

The Automatic Punching Press Model 1 by Quanzhou Sanxing Machinery Industry And Trade Co., Ltd. is a cutting-edge solution designed to streamline the punching process in rubber production lines. This advanced machine is engineered for high efficiency, precision, and durability, making it an ideal choice for modern industrial applications.

Detailed Product Description

Precision and Efficiency

- Advanced Punching Technology: The Automatic Punching Press Model 1 employs sophisticated punching technology to ensure high-precision and consistent results. It is designed to handle various rubber materials with remarkable accuracy.

- Automatic Operation: Features automated processes that enhance production efficiency by reducing manual intervention. This automation ensures consistent quality and speeds up the production cycle.

Robust Construction

- Heavy-Duty Build: Constructed with high-strength materials and a robust frame, the Automatic Punching Press Model 1 is built to withstand the demands of continuous operation in industrial settings. The design minimizes vibrations and enhances stability, contributing to precise punching.

- Durable Components: Incorporates high-quality, wear-resistant components that extend the lifespan of the machine and reduce maintenance needs. This durability ensures reliable performance over time.

Versatile Punching Capabilities

- Adjustable Punching Parameters: Equipped with adjustable settings to accommodate different rubber thicknesses and sizes. This flexibility allows the machine to handle a variety of production requirements with ease.

- High Throughput: Capable of processing large volumes of rubber efficiently, making it suitable for high-production environments and large-scale operations.

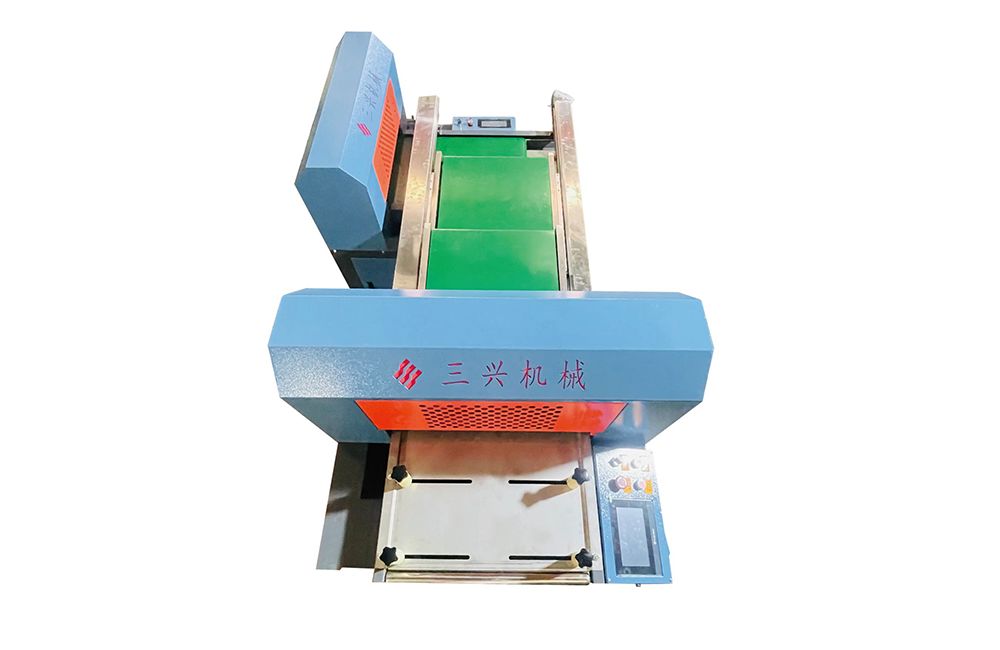

User-Friendly Interface

- Intuitive Controls: The control panel is designed for ease of use, allowing operators to quickly set up and adjust the machine. This user-friendly interface facilitates smooth operation and minimizes the learning curve for new users.

- Minimal Maintenance: Engineered for easy maintenance, the machine features accessible parts and straightforward cleaning procedures, which help to reduce downtime and ensure continuous operation.

Enhanced Safety Features

- Safety Guards: The Automatic Punching Press Model 1 is equipped with safety guards to protect operators from moving parts and potential hazards, ensuring a safer working environment.

- Emergency Stop Function: Includes an emergency stop button for immediate cessation of operations in case of an emergency, enhancing overall operator safety.

Integration and Compatibility

- Seamless Integration: Designed to integrate seamlessly with existing rubber production lines, enhancing overall workflow efficiency. The modular design allows for easy incorporation into various production setups.

- Wide Compatibility: Compatible with a range of rubber processing equipment, ensuring flexibility and adaptability in diverse production environments.

Precision Engineering and Quality Assurance

- High Standards of Engineering: Manufactured to the highest standards of precision, the Automatic Punching Press Model 1 meets rigorous industry specifications for reliability and performance.

- Certified Quality: The machine is certified to comply with stringent quality standards, reflecting our commitment to technological innovation and product excellence.

Future-Ready Technology

- Innovative Design: Incorporates advanced technology and design features that enhance performance and efficiency, making it adaptable to evolving industry needs.

- Upgrade Capabilities: Designed with features that allow for future upgrades and modifications, ensuring long-term relevance and effectiveness in dynamic production environments.

Why Choose the Automatic Punching Press Model 1 from Quanzhou Sanxing Machinery?

Quanzhou Sanxing Machinery Industry And Trade Co., Ltd., established in 2011, is dedicated to delivering top-quality industrial equipment and solutions. The Automatic Punching Press Model 1 embodies our commitment to precision engineering, innovation, and superior performance.

With a strong reputation for excellence, we lead the industry in providing advanced solutions that meet the evolving needs of our clients. The Automatic Punching Press Model 1 reflects our core values of quality assurance and technological innovation, supporting your business in achieving optimal operational efficiency and high-quality production. We look forward to partnering with domestic and international clients to drive success and growth in the competitive market.