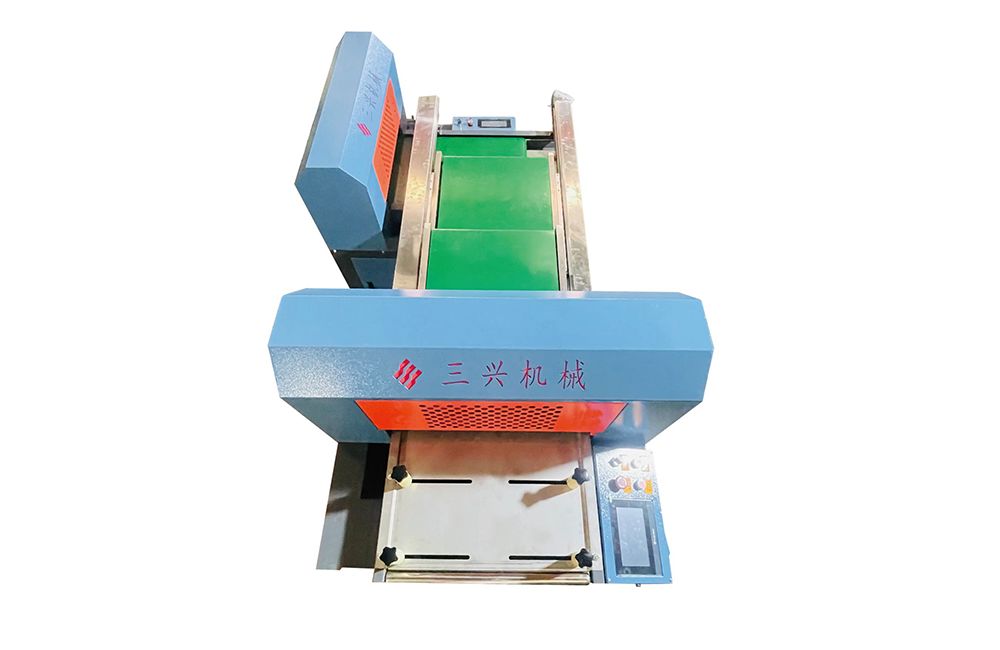

CNC Ice Water Chiller - Water-Cooled

The CNC Ice Water Chiller (Water-Cooled) is a state-of-the-art cooling solution designed specifically for rubber production lines. Manufactured by Quanzhou Sanxing Machinery Industry And Trade Co., Ltd., this machine integrates advanced CNC technology to deliver precise and efficient cooling, essential for maintaining optimal processing temperatures in rubber production. Its water-cooled design ensures consistent performance and reliability in various industrial environments, making it a critical component for achieving high-quality production outcomes.

Detailed Product Description

1. Advanced CNC Technology

The CNC Ice Water Chiller utilizes cutting-edge CNC (Computer Numerical Control) technology to provide precise temperature control and monitoring.

- Precision Cooling: CNC technology allows for exact temperature adjustments, ensuring that the cooling process is finely tuned to the specific requirements of rubber processing.

- Automated Control: The chiller features a sophisticated control system that automates the cooling process, minimizing manual intervention and enhancing operational efficiency.

2. Efficient Water-Cooled System

Designed for superior thermal management, the water-cooled system ensures effective heat dissipation and stable cooling performance.

- High-Efficiency Heat Exchange: The chiller employs a high-efficiency heat exchanger that maximizes the transfer of heat from the coolant to the water, ensuring rapid and effective cooling.

- Reduced Energy Consumption: By using water as a cooling medium, the system reduces energy consumption compared to air-cooled alternatives, offering both environmental and cost benefits.

3. Robust Construction and Durability

Built to withstand the demanding conditions of industrial environments, the CNC Ice Water Chiller is engineered for long-term reliability and durability.

- Heavy-Duty Materials: The unit is constructed from high-grade stainless steel and corrosion-resistant materials, ensuring longevity and resistance to harsh operating conditions.

- Durable Components: Key components such as the compressor and heat exchanger are designed for high performance and extended service life, reducing the need for frequent maintenance.

4. High-Performance Cooling Capacity

The chiller is capable of delivering substantial cooling power to meet the needs of large-scale rubber production lines.

- Adjustable Cooling Capacity: Operators can adjust the cooling capacity to match the specific needs of their production processes, ensuring optimal performance across a range of applications.

- Rapid Response Time: The system is designed to quickly achieve and maintain the desired temperature, minimizing downtime and improving overall production efficiency.

5. User-Friendly Interface

Featuring an intuitive control panel, the CNC Ice Water Chiller is easy to operate and configure.

- Digital Display: The control panel includes a digital display that provides real-time information on temperature, operation status, and system alerts.

- Customizable Settings: Operators can easily adjust settings such as temperature setpoints and cooling cycles through a user-friendly touchscreen interface.

6. Energy Efficiency and Environmental Impact

The chiller is designed with energy efficiency in mind, contributing to both cost savings and environmental sustainability.

- Low Power Consumption: The water-cooled system is optimized for low power consumption, reducing operating costs and minimizing the environmental footprint.

- Eco-Friendly Refrigerants: The chiller uses environmentally friendly refrigerants that comply with international standards for reducing greenhouse gas emissions.

7. Integrated Safety Features

Safety is a priority in the design of the CNC Ice Water Chiller, ensuring safe operation and protecting both the equipment and the operator.

- Automatic Shutdown: The system is equipped with automatic shutdown capabilities in the event of a malfunction or unsafe operating conditions, preventing damage and ensuring operator safety.

- Overheat Protection: Built-in overheat protection sensors monitor the system’s temperature, triggering cooling adjustments or shutdowns to prevent overheating.

8. Easy Maintenance and Serviceability

Designed for minimal maintenance, the chiller facilitates easy access to components for routine servicing and repairs.

- Modular Design: The modular construction allows for straightforward disassembly and access to internal components, simplifying maintenance tasks.

- Self-Diagnosis System: The chiller features a self-diagnosis system that alerts operators to potential issues and provides diagnostic information for efficient troubleshooting.

9. Versatile Applications

The CNC Ice Water Chiller is suitable for a wide range of rubber production applications and can be integrated into various production lines.

- Customizable Integration: The chiller can be tailored to fit the specific requirements of different rubber processing setups, ensuring compatibility with existing systems.

- Flexible Operation: It supports diverse cooling needs, making it ideal for both continuous and batch production processes.

Why Choose the CNC Ice Water Chiller from Quanzhou Sanxing Machinery?

Since its founding in 2011, Quanzhou Sanxing Machinery Industry And Trade Co., Ltd. has been dedicated to providing high-quality industrial equipment, including advanced cooling solutions. Our commitment to innovation, quality, and customer satisfaction is evident in the CNC Ice Water Chiller's design and performance.

Recognized as a national high-tech enterprise with multiple patents, we deliver cutting-edge technology and exceptional service to our clients. The CNC Ice Water Chiller is designed to enhance the efficiency and reliability of rubber production processes, offering precise cooling, energy savings, and robust performance.

Our core values of quality assurance, technological innovation, and customer-first service ensure that you are investing in a solution that not only meets your operational needs but also supports long-term success and growth. Whether upgrading existing systems or implementing new ones, our CNC Ice Water Chiller represents a commitment to excellence and a partner in achieving your production goals.