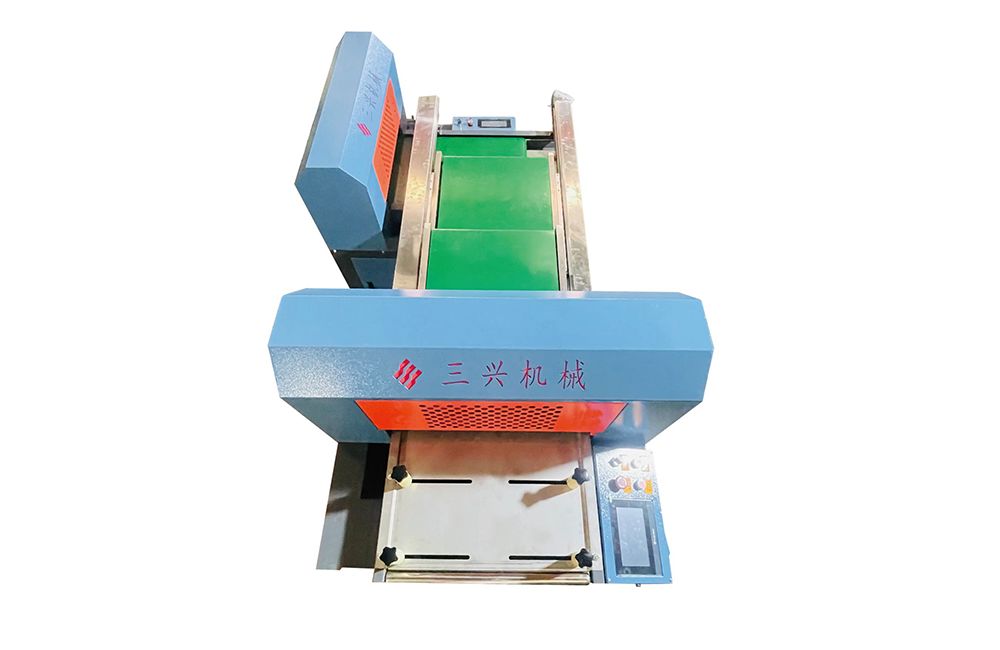

Rolling Cutter for Rubber Production Lines

The Rolling Cutter for Rubber Production Lines by Quanzhou Sanxing Machinery Industry And Trade Co., Ltd. represents our commitment to delivering high-quality, innovative solutions for the rubber industry. With its precision cutting technology, robust construction, and user-friendly operation, this machine is an excellent choice for enhancing the efficiency and consistency of rubber cutting processes. We look forward to partnering with our customers to drive success and achieve excellence in their manufacturing operations.

Detailed Product Description

Key Features:

Precision Cutting Mechanism:

- The Rolling Cutter is equipped with a high-precision cutting system that ensures uniformity and accuracy in the rubber cutting process. The machine features adjustable rollers and blades that can be fine-tuned to achieve desired cut dimensions, accommodating a range of rubber materials and thicknesses.

- The cutting mechanism is designed to handle both continuous and intermittent operation, providing flexibility for different production needs.

Robust Roller Design:

- The machine includes durable, high-strength rollers that are engineered to withstand the rigors of cutting various rubber compounds. These rollers are designed for smooth and consistent material feed, minimizing wear and extending the equipment’s lifespan.

- The rollers are adjustable to accommodate different material widths and thicknesses, ensuring versatility in handling diverse rubber products.

Efficient Material Handling:

- The Rolling Cutter features an advanced material handling system that includes adjustable feed rates and automatic material alignment. This system ensures smooth and accurate feeding of rubber into the cutting area, reducing the risk of misalignment and material waste.

- The machine is equipped with a conveyor system that facilitates the easy removal of cut rubber strips or sheets, enhancing overall workflow efficiency.

User-Friendly Control System:

- The machine is controlled via an intuitive digital interface that allows operators to easily set and monitor cutting parameters. The control system includes features such as programmable cut lengths, speed adjustments, and real-time monitoring of machine performance.

- Automated alerts and diagnostic functions are included to identify and address any operational issues promptly, ensuring minimal downtime and consistent production quality.

High Durability and Low Maintenance:

- Constructed from high-quality materials, the Rolling Cutter is built to endure the demands of continuous operation in industrial environments. Its robust design minimizes the need for frequent maintenance and reduces the total cost of ownership.

- The machine is equipped with easily accessible maintenance points and modular components, simplifying routine maintenance tasks and extending the equipment’s service life.

Energy Efficiency:

- The Rolling Cutter incorporates energy-efficient components and technologies that reduce power consumption while maintaining high performance. The machine’s design optimizes energy usage, contributing to lower operational costs and a reduced environmental footprint.

- It complies with environmental regulations and sustainability standards, making it a responsible choice for modern manufacturing processes.

Versatile Application:

- The Rolling Cutter is suitable for a wide range of applications within the rubber production line, including the cutting of rubber sheets, strips, and various profiles. Its versatility makes it ideal for use in different stages of rubber processing, from initial production to final product preparation.

- It can also be adapted for other industrial applications where precision cutting of flexible materials is required.

Service and Support:

Quanzhou Sanxing Machinery Industry And Trade Co., Ltd. is dedicated to providing comprehensive support for our Rolling Cutter. Our services include installation, commissioning, operator training, and ongoing technical support to ensure that our customers achieve optimal performance and satisfaction with our equipment.

Conclusion

The Rolling Cutter for Rubber Production Lines by Quanzhou Sanxing Machinery Industry And Trade Co., Ltd. represents our commitment to delivering high-quality, innovative solutions for the rubber industry. With its precision cutting technology, robust construction, and user-friendly operation, this machine is an excellent choice for enhancing the efficiency and consistency of rubber cutting processes. We look forward to partnering with our customers to drive success and achieve excellence in their manufacturing operations.