Dry Powder Tank

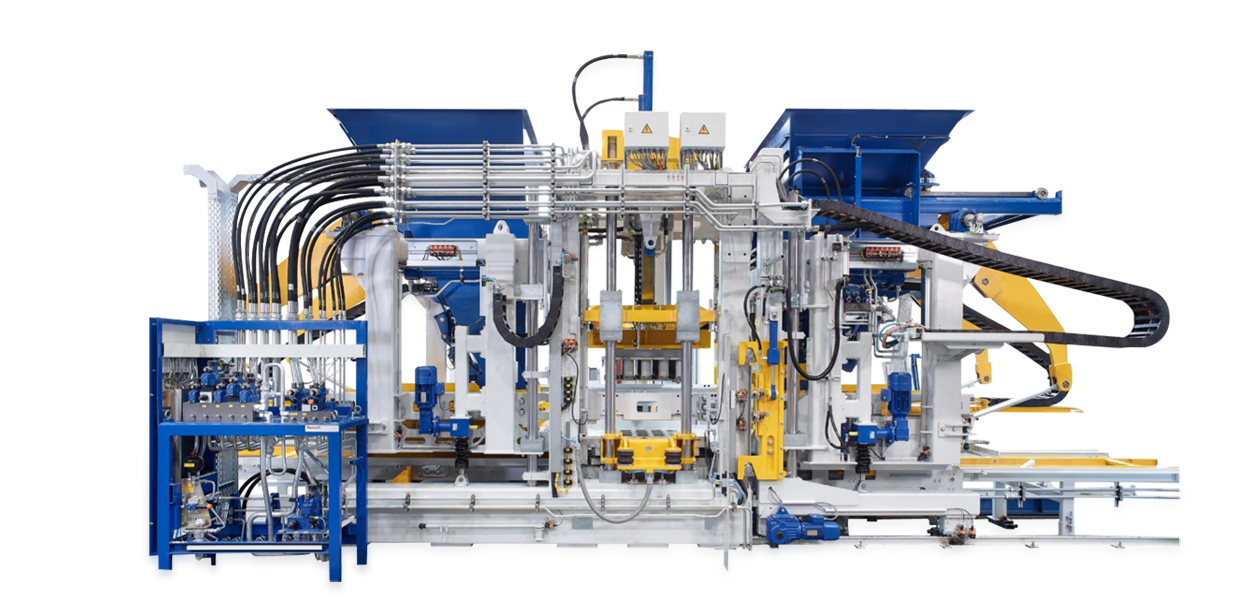

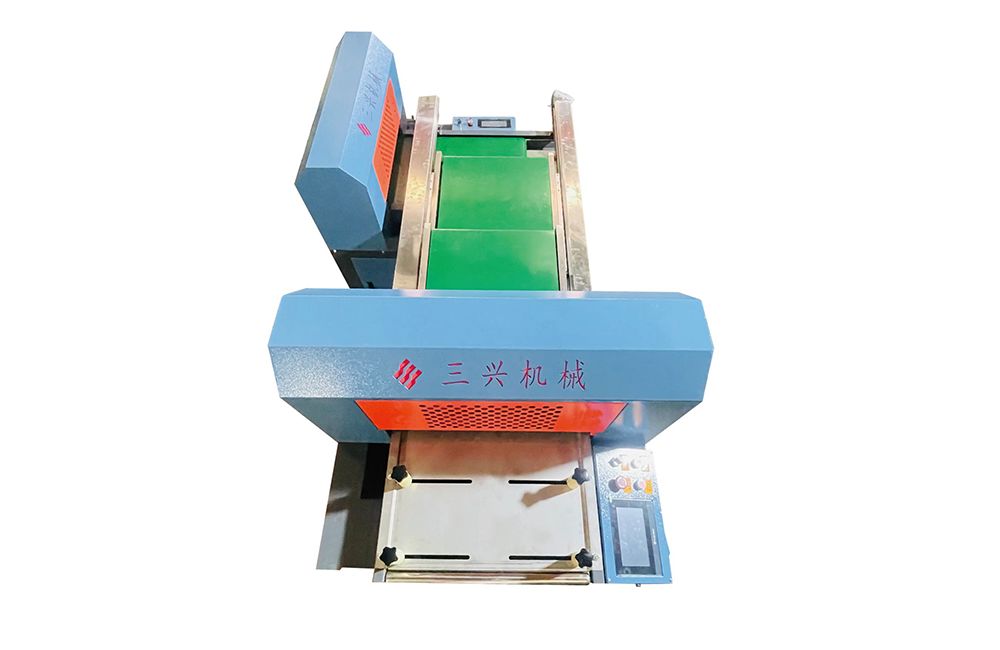

The Dry Powder Tank from Quanzhou Sanxing Machinery Industry And Trade Co., Ltd. is a high-efficiency, industrial-grade solution designed for rubber production lines. Specially engineered for the precise handling, storage, and distribution of dry powder materials, this tank ensures optimal performance in rubber compounding processes. Its advanced features make it an essential part of any rubber manufacturing facility, offering robust construction, reliable performance, and ease of integration.

Detailed Product Description

Key Features:

High-Quality Material Construction:

- The Dry Powder Tank is crafted from high-strength, corrosion-resistant materials, ensuring durability and a long service life even in harsh industrial environments. The tank’s structure is designed to resist wear and tear, providing a stable storage solution for dry powder used in rubber production.

- Its anti-corrosion and abrasion-resistant surface ensures that the tank remains intact over prolonged use, making it ideal for handling various powder compounds, including carbon black, silica, and other fillers used in rubber production.

Efficient Powder Handling:

- Designed to optimize the flow and handling of dry powders, the tank ensures minimal waste and maximum utilization of materials. The internal design minimizes the risk of powder clumping or blockages, ensuring a smooth and consistent supply of materials to the production line.

- With precision dispensing mechanisms, the tank facilitates accurate and consistent powder release, crucial for maintaining high-quality rubber compounds.

Large Capacity and Modular Design:

- The Dry Powder Tank is available in various capacities to suit different production needs, from small-scale operations to large industrial rubber plants. Its modular design allows for easy integration into existing rubber production lines, ensuring flexibility and adaptability based on production requirements.

- This modular approach also means that multiple tanks can be linked or installed based on production demands, making it easier to manage powder storage for different compounds.

Sealed Design for Clean Operation:

- The tank features a fully sealed design that prevents contamination from external particles, maintaining the purity and quality of stored powders. This feature is essential for ensuring the integrity of rubber formulations and maintaining a clean production environment.

- In addition, the sealed environment reduces the risk of powder spillage, leading to a cleaner, safer working environment and reducing material waste.

Automated Control System:

- Equipped with an advanced automated control system, the Dry Powder Tank allows for seamless operation with minimal human intervention. The control system monitors powder levels, ensures consistent flow, and can be integrated with the broader production line for synchronized operations.

- The automated system enhances operational efficiency by reducing downtime, minimizing the risk of human error, and improving the overall speed of material processing.

Easy Maintenance and Cleaning:

- Maintenance is simple and hassle-free due to the tank's accessible design. With easily removable components, the tank can be quickly cleaned and inspected, reducing downtime and increasing productivity.

- Routine maintenance and servicing are made straightforward, ensuring that the tank remains operational for extended periods without requiring frequent attention.

Customizable Options:

- The Dry Powder Tank can be customized to suit the specific needs of different rubber production processes. Customers can select the capacity, dimensions, and additional features such as material level sensors, pressure release systems, and even tailored configurations to handle specific types of powders or production challenges.

- The flexible design ensures that it can be adapted to meet both current and future production demands.

Safe and Reliable Operation:

- The tank is designed with safety in mind, featuring pressure relief systems and overload protection to ensure safe and smooth operation under all conditions. Its robust construction minimizes risks associated with material handling, such as leaks or pressure build-up.

- In addition, the use of advanced sealing mechanisms helps prevent dust and airborne particles from escaping, ensuring a cleaner working environment and compliance with safety regulations.

Energy-Efficient Performance:

- The Dry Powder Tank is designed with energy efficiency at its core, utilizing low-power motors and smart control systems that optimize operation while minimizing energy consumption. This leads to reduced operational costs and a more environmentally friendly production process.

- The automated powder management system ensures efficient use of materials, helping manufacturers cut down on waste and energy usage.

Applications:

- Rubber compounding and mixing

- Carbon black, silica, and other dry filler storage

- Storage and dispensing of additives for rubber production

- Dry powder handling for rubber extrusion and molding

Service and Support:

Quanzhou Sanxing Machinery Industry And Trade Co., Ltd. provides full service and support for the Dry Powder Tank, including installation, operator training, routine maintenance, and troubleshooting. Our team is committed to ensuring that your equipment runs at peak efficiency and meets all production demands. We offer tailored support packages to fit your unique needs and ensure the longevity of the equipment.

Conclusion

The Dry Powder Tank for rubber production lines by Quanzhou Sanxing Machinery Industry And Trade Co., Ltd. delivers reliable performance, robust construction, and seamless integration with any production setup. Its advanced features, including automated control, precise powder handling, and customizable design, make it a versatile and indispensable asset in the rubber manufacturing process. Whether you are looking to enhance efficiency, improve material handling, or increase production capacity, this tank is designed to meet all your requirements while maintaining superior quality and performance.