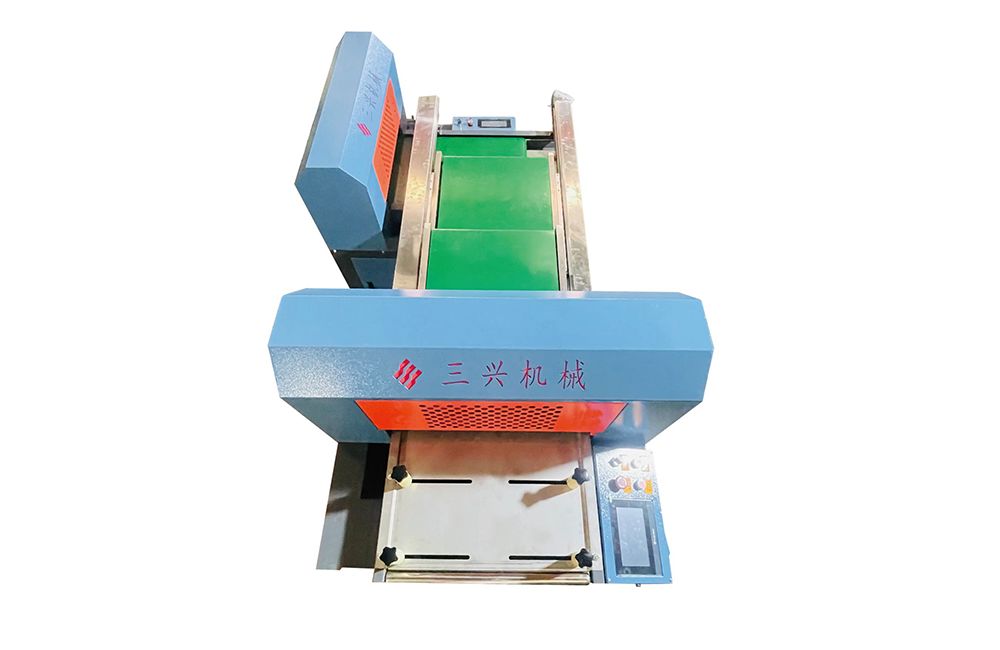

Fully Automatic Watering, Powdering, and Cutting Machine

The Fully Automatic Watering, Powdering, and Cutting Machine is a highly efficient and advanced piece of equipment designed for rubber production lines. Developed by Quanzhou Sanxing Machinery Industry And Trade Co., Ltd., this machine is specifically engineered to streamline the critical processes of water treatment, powdering, and cutting in rubber manufacturing. With its fully automated operation, this machine offers exceptional precision, productivity, and ease of use, making it an essential tool for large-scale rubber production facilities. Its cutting-edge features ensure reliable and consistent performance, helping manufacturers enhance their overall production quality.

Detailed Product Description

1. Fully Automated Process

This machine integrates three crucial operations—watering, powdering, and cutting—into one automated system, significantly reducing manual intervention and boosting production efficiency.

- Watering System: The machine features an advanced water treatment mechanism designed to apply a uniform water coating to rubber sheets, ensuring optimal moisture levels for subsequent processing.

- Powdering System: A sophisticated powder dispensing system ensures that a precise amount of powder is evenly distributed onto the rubber sheets, reducing stickiness and improving handling during production.

- Cutting Mechanism: The cutting process is automated with high-precision blades that deliver clean and accurate cuts, reducing waste and ensuring uniform product sizing.

2. High-Precision Control

The Fully Automatic Watering, Powdering, and Cutting Machine offers enhanced control over all three processes, ensuring superior accuracy and consistency in rubber sheet preparation.

- Touchscreen Interface: Operators can easily set and adjust parameters such as water volume, powder application, and cutting size using an intuitive touchscreen control panel.

- Automated Calibration: The machine features an automated calibration system that adjusts the operations based on material thickness and production requirements, ensuring consistent results without manual recalibration.

3. Efficient Powder Distribution

Proper powder application is critical to avoid material sticking and to ensure smooth downstream processing.

- Uniform Powder Coating: The powdering system is equipped with a precision distribution mechanism that guarantees even coverage across the entire surface of each rubber sheet, preventing over-powdering or under-powdering.

- Dust Control: The system is designed to minimize powder dust, reducing material waste and creating a cleaner working environment.

4. High-Speed Cutting

The cutting system is engineered for high-speed operation without sacrificing accuracy or quality.

- Fast and Efficient Cutting: With rapid blade movement, the machine can handle large volumes of rubber sheets quickly, making it ideal for high-demand production lines.

- Consistent Cutting Quality: The cutting blades are made from high-grade steel, providing long-lasting sharpness and ensuring precise cuts with minimal material deformation.

5. Superior Build Quality for Industrial Use

Engineered with durability in mind, this machine is built to withstand the rigors of industrial rubber production.

- Sturdy Frame: The machine’s structure is constructed from heavy-duty steel and corrosion-resistant materials, ensuring long-term reliability in harsh industrial environments.

- High-Durability Components: Critical parts such as the blades and powder dispensers are designed for extended use, reducing the need for frequent maintenance and replacements.

6. Safety Features

Operator safety is a priority in the design of this machine.

- Automated Safety Stops: Equipped with emergency stop buttons and sensors, the machine halts operations instantly in the event of any abnormality, preventing accidents and equipment damage.

- Protective Shields: Safety shields and barriers around moving parts provide additional protection for operators, reducing the risk of injury.

7. Low Maintenance and Easy Operation

Despite its sophisticated functionality, the machine is designed for easy operation and minimal maintenance.

- Self-Cleaning Functionality: The powdering and watering systems feature self-cleaning mechanisms that prevent material build-up and reduce the need for frequent cleaning.

- Modular Design: The modular construction allows for quick access to internal components, making maintenance tasks straightforward and reducing downtime.

8. Energy-Efficient Design

Incorporating advanced energy-saving technology, this machine is both eco-friendly and cost-efficient.

- Low Energy Consumption: The machine is designed to optimize power usage, ensuring high efficiency without excessive energy expenditure.

- Sustainable Production: By reducing material waste and optimizing water and powder use, the machine contributes to more sustainable rubber production processes.

9. Versatile and Adaptable

The machine is capable of processing a wide variety of rubber types and is suitable for diverse industrial applications.

- Multi-Material Compatibility: Whether processing natural or synthetic rubber, this machine ensures consistent results across various rubber materials.

- Customizable Settings: Operators can easily adjust the machine to accommodate different production specifications, allowing it to fit seamlessly into a variety of production lines.

Why Choose the Fully Automatic Watering, Powdering, and Cutting Machine from Quanzhou Sanxing Machinery?

Since its establishment in 2011, Quanzhou Sanxing Machinery Industry And Trade Co., Ltd. has been a leading provider of high-quality industrial equipment, specializing in rubber, plastic, and refrigeration machinery. Our commitment to innovation, quality, and customer satisfaction is reflected in the advanced technology and superior performance of our Fully Automatic Watering, Powdering, and Cutting Machine.

Recognized as a national high-tech enterprise and holder of several patents, we take pride in delivering reliable and cutting-edge solutions to our customers. This machine is designed to help manufacturers improve efficiency, reduce costs, and enhance product quality. Whether you're looking to upgrade your existing production line or establish a new one, our fully automated system is the perfect addition to your operations, offering both flexibility and dependability.

Our dedication to quality assurance, technological innovation, and customer-first service ensures that you are not just investing in a machine but a long-term partnership in growth and success.