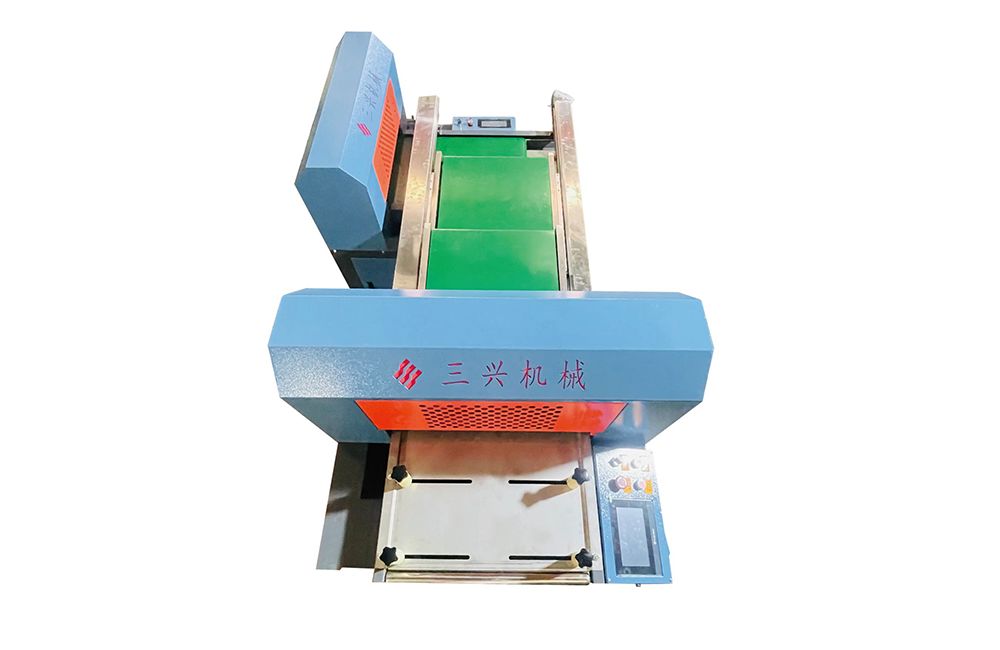

CNC Cutting Machine

The CNC Cutting Machine is an advanced, high-precision solution designed for cutting rubber materials in industrial production lines. Manufactured by Quanzhou Sanxing Machinery Industry And Trade Co., Ltd., this machine features state-of-the-art CNC technology, ensuring unparalleled accuracy and efficiency in rubber processing. Its robust design and versatile capabilities make it an essential tool for achieving precise cuts and maintaining consistent quality in rubber products.

Detailed Product Description

1. Cutting Precision and Efficiency

The CNC Cutting Machine integrates advanced CNC (Computer Numerical Control) technology, providing exceptional cutting precision and operational efficiency.

- High Accuracy: Equipped with a sophisticated CNC system, the machine delivers precise and repeatable cuts, essential for maintaining high-quality standards in rubber production.

- Rapid Operation: The cutting speed can be easily adjusted to match production requirements, allowing for rapid processing without compromising accuracy.

2. Advanced Control System

The machine features a user-friendly control interface that simplifies operation and customization.

- Digital Control Panel: The control panel includes a digital display for real-time monitoring of cutting parameters, including speed, depth, and cutting patterns.

- Programmable Settings: Operators can program and save multiple cutting configurations, facilitating quick adjustments and efficient handling of different rubber materials and shapes.

3. Robust Construction and Durability

Designed for heavy-duty industrial use, the CNC Cutting Machine is built to withstand the rigors of continuous operation.

- Sturdy Build: Constructed from high-strength materials, the machine offers durability and stability, ensuring consistent performance over time.

- Wear-Resistant Components: Key components, such as the cutting blades and drive mechanisms, are designed to resist wear and tear, minimizing maintenance needs and extending service life.

4. Versatility and Customization

The machine is highly versatile, capable of handling various types of rubber materials and cutting requirements.

- Adjustable Cutting Parameters: The machine allows for adjustments in cutting depth, angle, and speed, making it suitable for a wide range of rubber products, from thin sheets to thick blocks.

- Customizable Fixtures: Optional fixtures and attachments enable customization for specific cutting tasks, enhancing the machine's adaptability to different production needs.

5. Enhanced Safety Features

Safety is a key consideration in the design of the CNC Cutting Machine, ensuring a secure working environment for operators.

- Emergency Stop: An emergency stop function is integrated into the control panel, allowing for immediate cessation of operations in case of an emergency.

- Safety Guards: The machine is equipped with safety guards and sensors to prevent accidental contact with moving parts, enhancing overall safety during operation.

6. Energy Efficiency and Environmental Impact

The CNC Cutting Machine is designed to be energy-efficient, contributing to lower operating costs and reduced environmental impact.

- Low Power Consumption: The machine’s design minimizes energy use, offering cost savings and environmental benefits.

- Eco-Friendly Operation: The cutting process generates minimal waste, supporting sustainable production practices.

7. Easy Maintenance and Serviceability

Maintenance of the CNC Cutting Machine is straightforward, with features designed to simplify servicing and repairs.

- Accessible Design: The machine’s modular design allows easy access to internal components for routine maintenance and repairs.

- Self-Diagnostic System: An integrated self-diagnostic system alerts operators to potential issues, facilitating quick troubleshooting and minimizing downtime.

8. Integration and Compatibility

The CNC Cutting Machine is designed to integrate seamlessly into existing rubber production lines and systems.

- Flexible Integration: The machine can be easily incorporated into various production setups, enhancing its versatility and utility in different manufacturing environments.

- Compatibility: It supports integration with other equipment and systems, providing a cohesive solution for comprehensive rubber processing.

Why Choose the CNC Cutting Machine from Quanzhou Sanxing Machinery?

Founded in 2011, Quanzhou Sanxing Machinery Industry And Trade Co., Ltd. is committed to delivering high-quality industrial equipment, including advanced cutting solutions. Our dedication to innovation, quality, and customer satisfaction is reflected in the CNC Cutting Machine’s design and performance.

With a strong emphasis on quality assurance, technological advancement, and customer-first service, we offer solutions that meet the highest standards of performance and reliability. Our CNC Cutting Machine is engineered to enhance the efficiency and accuracy of rubber production processes, supporting your business in achieving superior product quality and operational excellence.

As a recognized national high-tech enterprise with numerous patents, we are dedicated to advancing technology and delivering exceptional value to our clients. The CNC Cutting Machine represents our commitment to providing advanced, reliable, and efficient solutions for the rubber industry, helping you stay competitive and achieve your production goals.