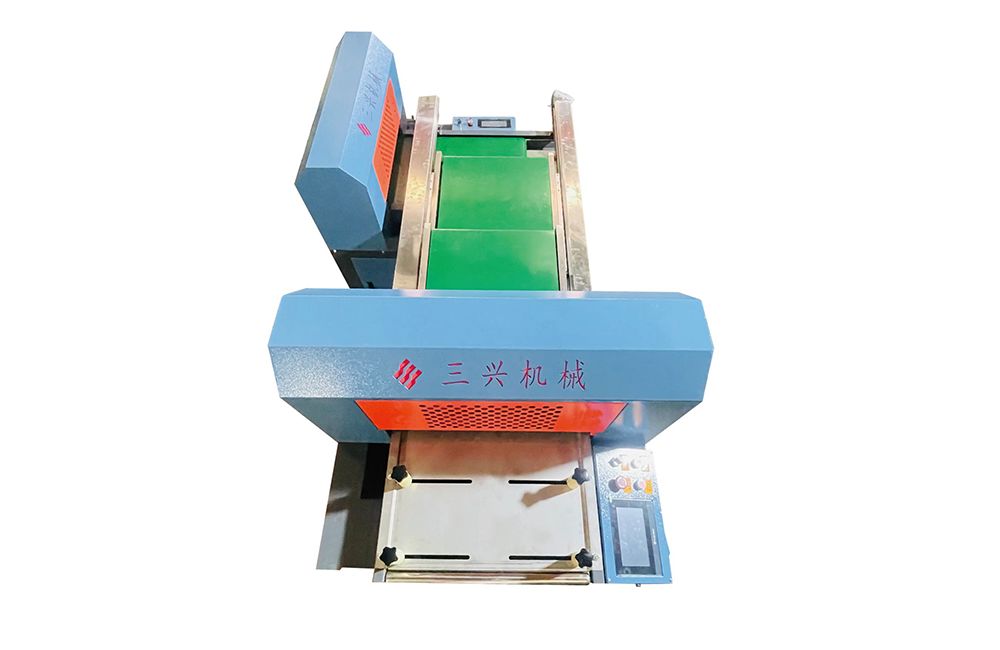

Hydraulic Slicing Machine with Water Tank

The Hydraulic Slicing Machine with Water Tank is a state-of-the-art solution designed to enhance the efficiency and precision of rubber processing within industrial production lines. Developed by Quanzhou Sanxing Machinery Industry And Trade Co., Ltd., this machine integrates advanced hydraulic technology with a robust water tank system, providing a comprehensive solution for cutting and cooling rubber materials.

Detailed Product Description

1. Advanced Hydraulic Cutting Technology

The Hydraulic Slicing Machine utilizes advanced hydraulic systems to deliver precise and efficient cutting of rubber materials, ensuring high-quality results and consistent performance.

- Hydraulic Precision Cutting: The machine employs hydraulic pressure to achieve accurate and consistent slicing of rubber sheets, enhancing cutting precision and reducing material waste.

- Adjustable Cutting Thickness: Operators can easily adjust the cutting thickness to meet specific production requirements, providing flexibility for various applications.

2. Integrated Water Tank System

The water tank system is designed to efficiently cool and cleanse rubber materials during the cutting process, improving overall performance and extending the lifespan of the equipment.

- Effective Cooling: The integrated water tank cools the rubber materials as they are cut, preventing overheating and maintaining optimal material properties.

- Efficient Cleansing: The water tank also facilitates the cleaning of rubber materials, removing debris and residues to ensure a clean and smooth cutting process.

3. Robust Construction and Durability

Constructed from high-quality materials, the Hydraulic Slicing Machine with Water Tank is designed to withstand demanding industrial environments and provide long-lasting performance.

- Heavy-Duty Frame: The machine features a robust frame and components, built to handle high operational loads and resist wear and tear.

- Corrosion-Resistant Materials: Components exposed to water and cutting debris are made from corrosion-resistant materials, ensuring durability and reducing maintenance needs.

4. User-Friendly Operation and Controls

The machine is designed with user-friendly controls and features, making it easy for operators to manage and optimize the cutting process.

- Intuitive Control Panel: The control panel provides easy access to machine settings, allowing operators to adjust cutting parameters and monitor performance with ease.

- Automatic Operation Modes: The machine includes automatic operation modes for common cutting tasks, simplifying operation and reducing the need for manual adjustments.

5. High Efficiency and Productivity

The Hydraulic Slicing Machine with Water Tank is engineered for high efficiency and productivity, enhancing overall production output and minimizing downtime.

- Fast Cutting Speed: The machine's hydraulic system delivers rapid cutting speeds, increasing production rates and reducing cycle times.

- Minimal Downtime: The integrated water tank and automatic features contribute to reduced maintenance and downtime, ensuring continuous operation and maximizing productivity.

6. Precision Engineering and Quality Assurance

Each component of the Hydraulic Slicing Machine is engineered for precision and reliability, reflecting our commitment to quality and innovation.

- Precision Manufacturing: The machine is manufactured to high standards, with precise tolerances and high-quality components that ensure consistent performance and accuracy.

- Quality Certification: The machine is built in accordance with stringent quality standards and has received multiple certifications, underscoring our commitment to excellence.

7. Versatility and Customization

The Hydraulic Slicing Machine can be customized to meet specific production needs, offering versatility for different rubber processing applications.

- Customizable Specifications: The machine's specifications can be tailored to accommodate various sizes and types of rubber materials, providing flexibility for different production scenarios.

- Adaptable Design: The design of the machine allows for easy integration into existing production lines, ensuring compatibility with various production setups.

8. Enhanced Safety Features

Safety is a top priority in the design of the Hydraulic Slicing Machine, ensuring a secure working environment for operators.

- Safety Guards and Sensors: The machine includes safety guards and sensors to prevent accidents and protect operators during operation.

- Emergency Stop Function: An emergency stop function is available for immediate cessation of operations in case of emergencies, enhancing overall safety.

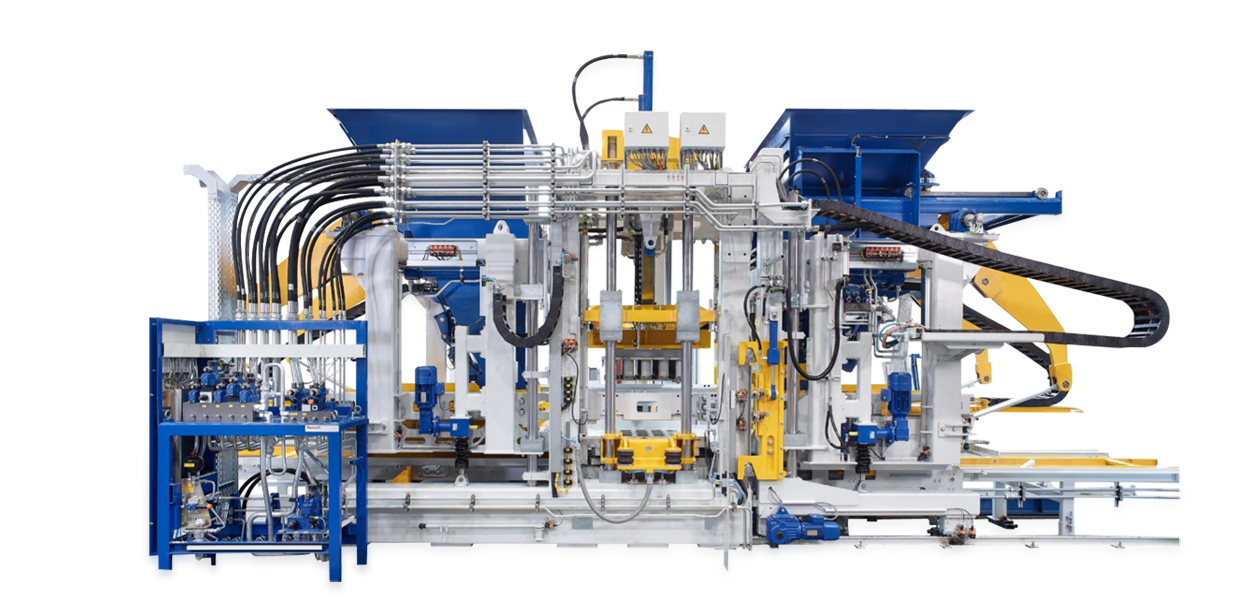

Why Choose the Hydraulic Slicing Machine with Water Tank from Quanzhou Sanxing Machinery?

Since its inception in 2011, Quanzhou Sanxing Machinery Industry And Trade Co., Ltd. has been committed to delivering high-quality and innovative industrial equipment. Our Hydraulic Slicing Machine with Water Tank exemplifies our dedication to providing advanced solutions for rubber processing, combining precision engineering with practical design.

With numerous patents and recognition as a national high-tech enterprise, we continue to lead the industry in technological innovation and customer satisfaction. The Hydraulic Slicing Machine with Water Tank reflects our core values of quality assurance and technological excellence, supporting your business in achieving operational efficiency and excellence in rubber processing. We look forward to collaborating with domestic and international clients to advance technology and achieve mutual success in the competitive market.