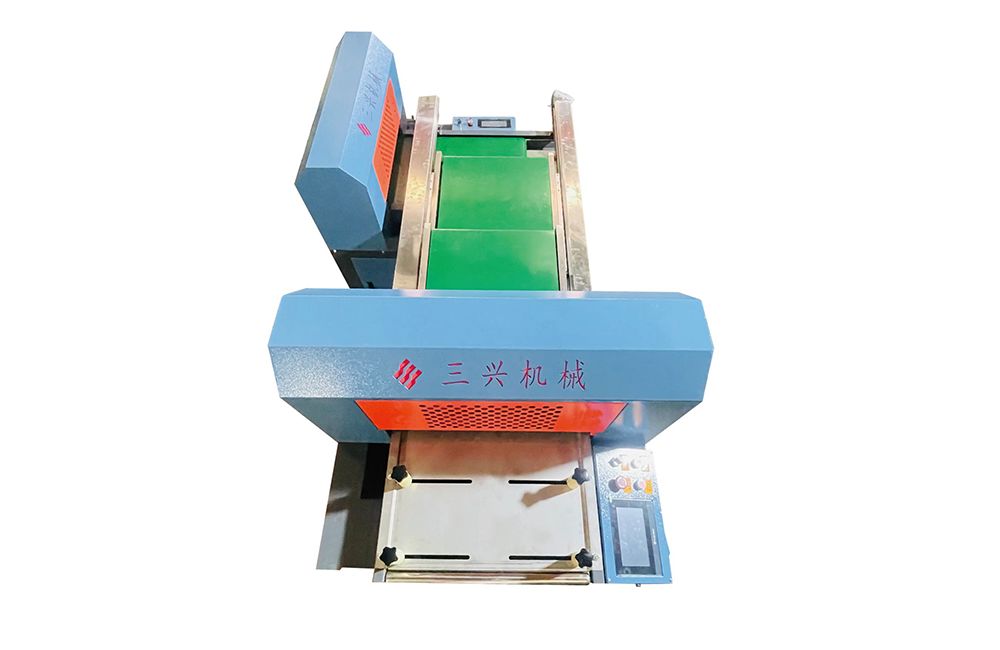

Water Trough with Air Cabinet

The Water Trough with Air Cabinet is an advanced and highly efficient piece of equipment designed for use in rubber production lines. Developed by Quanzhou Sanxing Machinery Industry And Trade Co., Ltd., this system integrates a water trough for cleaning and cooling rubber products with an air cabinet for rapid drying. This combined unit optimizes the production process by reducing time and ensuring a high-quality finish. Built with durable materials and innovative design, it is ideal for enhancing the performance of rubber products in various stages of production.

Detailed Product Description

1. Integrated Water and Air System

The Water Trough with Air Cabinet combines two essential processes—cleaning and drying—into one cohesive unit. This integration improves efficiency and saves space on the production line.

- Water Trough: The water trough efficiently cools down rubber products after heating or molding stages, removing residual particles, and cleaning the product surface to ensure a smooth finish. The size of the trough can be adjusted to accommodate different product dimensions, offering flexibility for varying production needs.

- Air Cabinet: Immediately after the water cleaning process, the built-in air cabinet uses high-pressure airflow to dry the rubber products quickly and uniformly. This rapid drying minimizes water spots, ensuring the products are ready for the next stage of production without delays.

2. Durable and Corrosion-Resistant Construction

The water trough and air cabinet are constructed with high-grade stainless steel, ensuring durability and corrosion resistance even when exposed to harsh chemicals and water over prolonged periods.

- High-Quality Materials: The materials used in construction ensure that the equipment can withstand the high demands of continuous operation. The water trough is also designed with easy drainage systems to prevent water buildup and reduce maintenance downtime.

- Corrosion Protection: The use of stainless steel extends the life of the equipment by preventing rust and corrosion, even in wet environments. This enhances long-term performance and reduces maintenance costs.

3. Efficient Cooling and Drying

By combining cooling and drying into one seamless process, this system significantly improves production efficiency.

- Optimized Cooling: The water trough provides consistent cooling to rubber products, stabilizing their form and preparing them for further processing. This ensures that each product maintains high-quality standards.

- Rapid Drying: The air cabinet employs a powerful air circulation system to remove water from the product’s surface quickly. This rapid drying process reduces the risk of contamination and ensures that the products are ready for further handling.

4. Easy to Operate and Maintain

The Water Trough with Air Cabinet is designed with user-friendly controls and accessible components for easy maintenance.

- Simple Operation: Operators can easily control water temperature, air pressure, and drying time using the intuitive control panel, making it easier to adapt the process to specific product requirements.

- Low Maintenance: The equipment is designed with a self-cleaning function that reduces the accumulation of debris, keeping the machine in optimal condition and minimizing the need for regular maintenance.

5. Customizable for Different Production Needs

This system is customizable in terms of size and capacity, allowing manufacturers to tailor the equipment to their specific production requirements. Whether you’re working with small batches or large-scale production, the Water Trough with Air Cabinet can be adjusted to fit your needs perfectly.

Why Choose Quanzhou Sanxing Machinery?

At Quanzhou Sanxing Machinery Industry And Trade Co., Ltd., we are committed to providing the best equipment and solutions for our customers. Established in 2011, we have earned the trust and recognition of our clients by delivering top-quality products and innovative solutions. With our focus on technical excellence, precision engineering, and exceptional customer service, we ensure that our machines help you optimize your production line and achieve your manufacturing goals.